lignoloc® Holznägel

Nachhaltig bauen - Nagel für Nagel

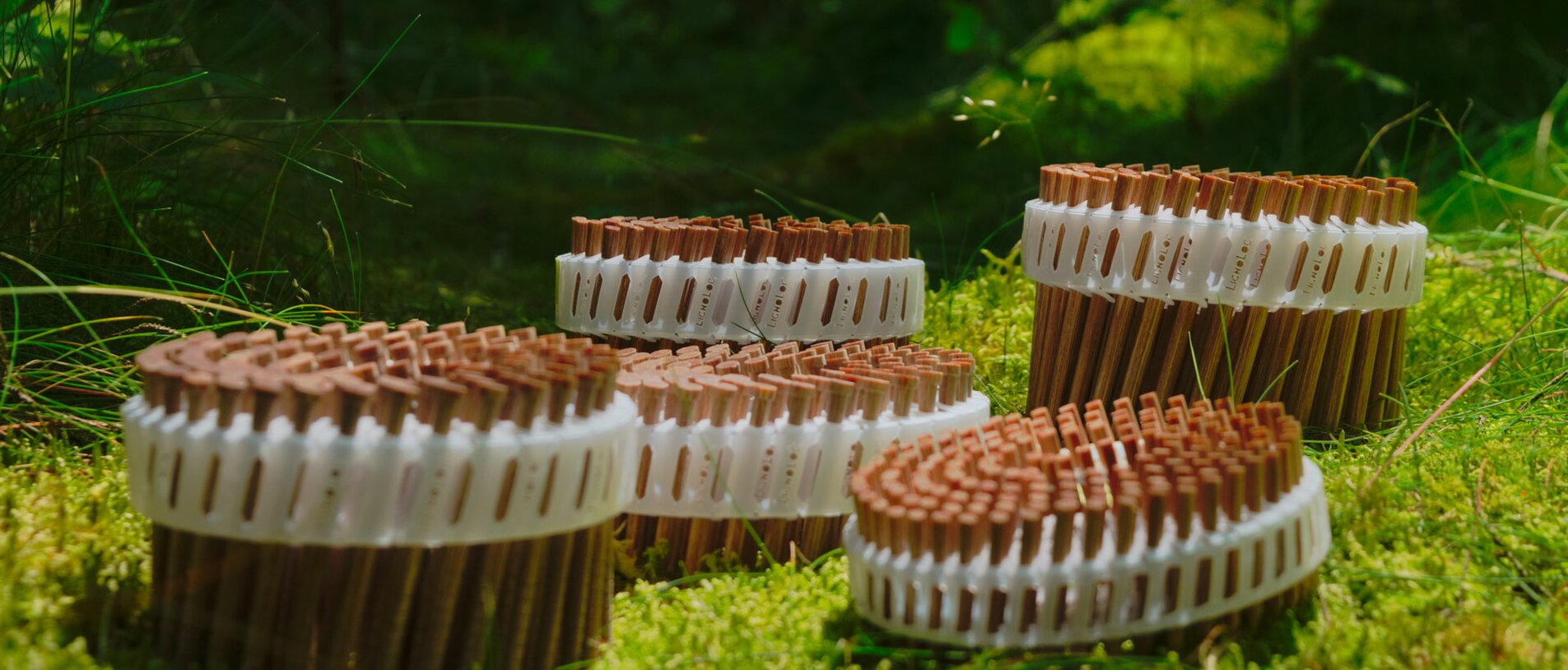

LIGNOLOC® ist das erste magazinierte Nagelsystem aus dem nachwachsenden Rohstoff Buchenholz, das Leistung und Nachhaltigkeit perfekt verbindet. Ideal für alle Holzbauunternehmen, die ihre Projekte kreislaufgerecht, leim- und metallfrei, aber auch hocheffizient umsetzen wollen.

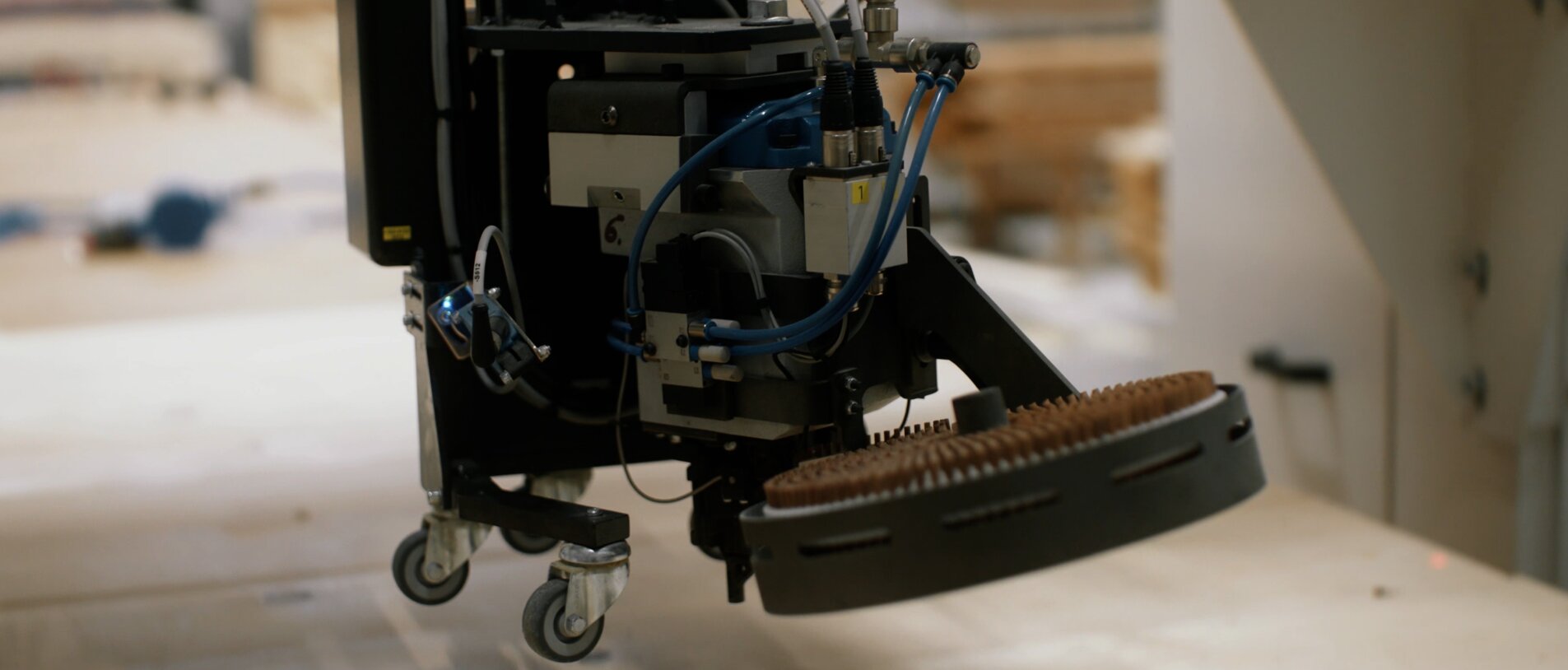

Mit LIGNOLOC® haben wir Befestigungstechnik ganz neu gedacht und ein nachhaltiges, traditionelles Befestigungsmittel zurückgebracht und es so weiterentwickelt, dass es den Anforderungen von heute gerecht wird und die Zukunft des Bauens nachhaltig verändert. LIGNOLOC® ist der erste schießbare Holznagel der Welt, ideal für die industrielle Fertigung und ökologische Holzbearbeitung. Mit dem eigens entwickelten FASCO® Druckluftnagler der LIGNOLOC® Edition lassen sich die Nägel problemlos in Holz und Holzwerkstoffe einschießen und garantieren eine feste, unlösbare Verbindung. LIGNOLOC® ist das nachhaltigste professionelle Befestigungssystem auf dem Markt, das den CO₂-Ausstoß im Vergleich zu herkömmlichen Systemen um 66% reduziert und die Kreislaufwirtschaft unterstützt.

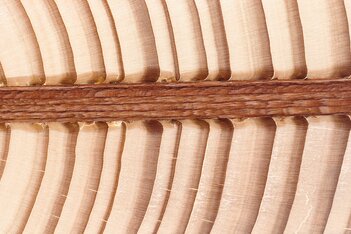

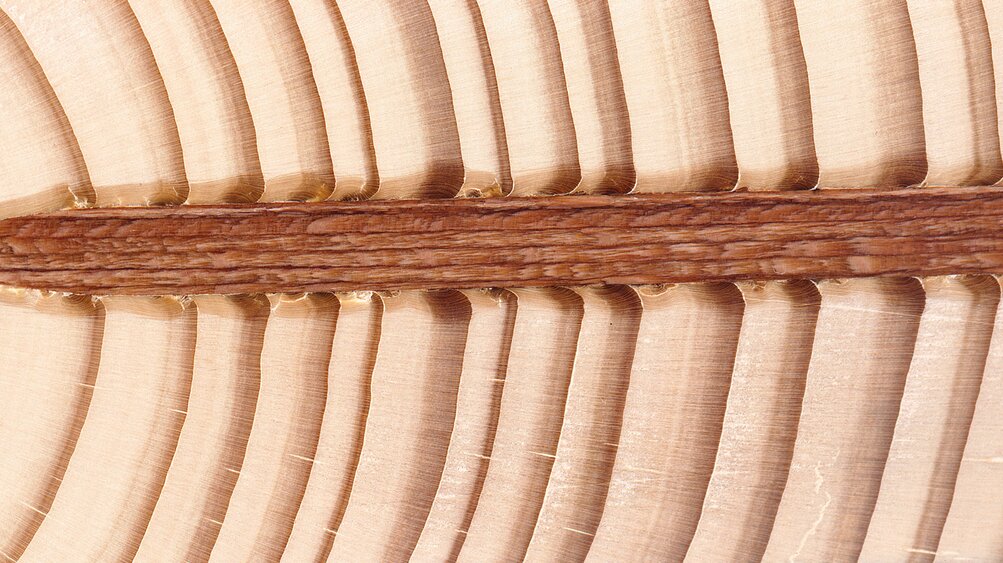

Mikroskopische Aufnahme der Verbindung zwischen dem LIGNOLOC® Holznagel und dem umgebenden Trägerholz

der holzschweisseffekt

Schon gewusst? LIGNOLOC® Holznägel überzeugen durch hohe Haltekraft. Dank Lignin Welding. Durch die spezielle Ausprägung der LIGNOLOC® Nagelspitze und die Wärme, die durch die Reibung beim Eintreiben des Nagels entsteht, verschmilzt das Lignin des Holznagels mit dem des Umgebungsholzes zu einer stoffreinen Verbindung. Entdecken Sie jetzt in unserem Video, wie dieser beeindruckende Effekt funktioniert.

Zulassungen

Die ETA gilt für die LIGNOLOC® Holznägel mit und ohne Kopf und ermöglicht die Planung, Bemessung und Ausführung von tragenden Verbindungen im Holzrahmenbau. Die Festlegungen basieren auf einer angenommenen Nutzungsdauer der LIGNOLOC® Nägel von 50 Jahren.

LIGNOLOC®, das neuartige Befestigungskonzept, begeistert nicht nur uns. Der erste schießbare Holznagel der Welt überzeugte auch den Expertenrat und hat seit August 2020 die offizielle allgemeine bauaufsichtliche Zulassung der DIBt (Deutsches Institut für Bautechnik) für „Tragende Holzverbindungen unter Verwendung von LIGNOLOC® Holznägeln“.

DIE ZUKUNFT DES HOLZBAUS - UNSERE MISSION

Mit LIGNOLOC® ist es möglich, Holz zu Holz mit Holz zu verbinden. Und damit die natürlichste und ökologischste Verbindung überhaupt herzustellen.

Lignoloc® holznagel systeme

Mit dem LIGNOLOC® System eröffnen sich viele Möglichkeiten für Sie. Die Nägel gibt es in verschiedenen Durchmessern und Längen. Seit Januar 2023 ganz neu auch mit Kopf perfekt für Anwendungen im Außenbereich. Für das Portfolio der Nägel gibt es zwei Handgeräte und zwei Nagelköpfe für Roboter oder Portal-CNC-Maschinen für stationäre Anwendungen. Damit passt es sich genau Ihren Anforderungen an.

test anfordern

Bitte tragen Sie hier Ihre Daten ein und klicken Sie auf Absenden. Innerhalb weniger Tage wird sich einer unserer Partner per Telefon oder Mail bei Ihnen melden, um einen Test des LIGNOLOC® Holznagelsystems zu vereinbaren.

Anwendungsbereiche von lignoloc®

Mit dem LIGNOLOC® System von BECK stehen Ihnen unzählige Anwendungsmöglichkeiten offen – egal, ob im Innen- oder Außenbereich oder in korrosionsanfälligen Umgebungen.

Anwendungen im Überblick

-

Holzrahmenbau

-

Massivholzkonstruktionen: LCLT, CLT, NLT

-

Holzfassaden

-

Zäune

-

Möbel

-

Paletten & Kisten

-

Sauna

-

Innenwandverkleidungen

-

Fußböden: OSB- und Echtholzdielen

-

Boote

-

Renovierungsarbeiten mit Altholz

-

CNC-Anwendungen (Prototypen)

-

Holzsärge

-

und vieles mehr

Lignoloc® im massivholzbau

LIGNOLOC® Holznägel können auf verschiedene Weise bei der Produktion von Mehrschicht-Massivholzplatten eingesetzt werden. Je nach Fertigungsverfahren werden sie zur temporären Fixierung der Schichten oder als Ersatz von Aluminiumnägeln und Holzdübeln eingesetzt. Sie bringen aber auch ganz neue Verarbeitungsmethoden hervor. Dies bedeutet zeitliche und ökologische Vorteile für die Industrie.

ausgewählte LIGNOLOC® referenzen

Mit LIGNOLOC® haben wir ein neues, wegweisendes Produkt entwickelt, dessen Idee und einzigartige Eigenschaften begeistern. LIGNOLOC® hat schon viele Auszeichnungen, wie z.B. den German Design Award für innovatives Produktdesign, gewonnen. Wir feiern zwar jeden Preis, aber noch mehr begeistern uns die umgesetzten Projekte und der Erfolg unserer Kunden mit LIGNOLOC® – denn darum geht es.

"Als innovativer Handwerksbetrieb sind wir immer offen für Neues. Die Holzfassade unserer neuen Werkshalle haben wir mit LIGNOLOC® montiert und sind begeistert. Wir werden das LIGNOLOC® System auch unseren Kunden empfehlen."

FAQ

Das kommt ganz auf die Dichte der Holzart an. Wie im Eurocode 5 Tabelle 8.2 beschrieben, muss bei der Befestigung von Hölzern mit stiftförmigen Verbindungsmitteln auf die Dichte der Holzart geachtet werden. Nur Hölzer mit einer Dichte kleiner als 500 kg/m³ dürfen ohne Vorbohren genagelt werden.

Ja. Wir empfehlen die Verwendung des FASCO® F44 LIGNOLOC® von BECK, da dieses Gerät für die speziellen Anforderungen des Holznagels entwickelt wurde. Der größere Durchgang im Vorschubmechanismus sowie die Führungsklappen sind für ein perfektes Schussergebnis wichtig.

Abhängig von der Nageldimension und dem zu vergleichenden metallischem Befestigungsmittel kann die CO₂-Emission bis zu 66% geringer sein.

Das Kunststoffband ist aktueller Stand der Technik und ermöglicht, LIGNOLOC® rückstandsfrei zu verarbeiten. Das Kunststoffband kann problemlos dem Recycling zugeführt werden.

LIGNOLOC® mit Kopf können als Ersatz für Fassadenschrauben verwendet werden. Horizontale und vertikale Schalungen aus Nadelhölzern lassen sich mit LIGNOLOC® auf Holzunterkonstruktionen befestigen.

Wie auch bei metallischen Nägeln, kann es zu Beschädigungen des LIGNOLOC® Nagels führen, wenn beispielsweise eine sehr harte Stelle in der Unterkonstruktion getroffen wird.

BECK bietet in seiner Gerätelinie FASCO® für die Verarbeitung des Nagels ein spezialisiertes Setzgerät an, welches für die fehlerfreie Verarbeitung der Nägel optimiert wurde. Ältere Modelle der F60 Baureihe können für die Verarbeitung der LIGNOLOC® mit Kopf mit einem Umbausatz von FASCO® angepasst werden.

Das F60 Nagelsetzgerät sollte an einer unauffälligen Stelle der Fassade auf die richtige Tiefe und den richtigen Luftdruck eingestellt werden. Unter Beibehaltung dieser Einstellung und unter gleichmäßigem Anpressdruck des Gerätes an die Fassade durch den Anwender ist eine gleichmäßige Eintreibtiefe zu erreichen. Starke Streuungen der Holzdichten innerhalb der anzubringenden Materialien, kann zu Schwankungen führen, die durch Nachjustieren auszugleichen sind.

In seltenen Fällen kommt es zu kleinen Absplitterungen am Nagelkopf. Diese Absplitterungen beeinträchtigen die Haltbarkeit des Nagels nicht.